Design & Manufacturing of Molds

Design & Manufacturing of Molds

We design high-performance, high-durability molds and dies (hereafter "molds and dies" will be written as "molds" for short), upon our experience and know-how. Using state-of-the-art equipment, we offer high-precision and highly wear-resistant molds. Except non-conventional process, we perform almost all mold-manufacturing processes in-house, from six-surface cutting-grinding and heat treatment to finishing. We also handle molds that require special resin injection, such as binary resin or heat-and-cool injection.

Design

- - Drawing for 2D assembly and components

- - Preparation of 3D model data and NC data

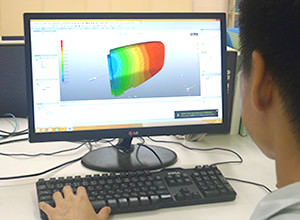

- - Preliminary investigation by CAE (flow analysis) and proposal for quality improvement / cost reduction

- - Design reviews with customers, etc.

Manufacturing

- - Basic process (heat treatment, surface treatment, face cutting and grinding, etc.)

- - Basic machining (milling, drilling, etc.)

- - Preliminary investigation by CAE (flow analysis) and proposal for quality improvement / cost reduction

- - Insert machining (high-speed milling, wire electro discharge machining (WEDM) and electro discharge machining (EDM), etc.)

-

- Development of molds

- In our quest for high productivity of resin injection and die casting, we actively explore our ideas and planning capabilities as well as advanced IT technology to produce our valued molds. Through extensive 3D modeling studies, we suggest molds with complicated shapes, which have been considered impossible to manufacture. By introducing high performance CAD/CAM/CAE systems, we assist with the projects with highly complicated curved surface shape or complex structure.

We keep working on the improvement of our productivity, assembly-time and our quality.

-

- Molds for prototype

- We recognize the key role of prototype molds playing in the early detection of problems which may occur at the mass production. Our prototype molds should be used to contribute to the improvement of productivity.

-

- Molds for mass production

- In order to improve the quality and durability of molds, we perform almost all operations process in-house. By employing the most advanced CAD/CAM/CAE systems and other state-of-the-art machines, we carry out high quality and high precision machining at each step. For the sake of mold's functionality and its maintenance, we produce every part within the specified tolerance so that fitting processes are unnecessary.

-

- Machining parts for molds

- We employ a wide variety of machine-tools, from general-purpose machines to the latest numerically-controlled ones, and from laser ablation machines to heat treatment furnaces, which enabling us to manufacture high precision parts.

Control

Control

Based on our extensive experience in handling wide range of products through years of molds manufacturing, we acquired our knowledge on accurately controlling complex shapes, even hard-to-measure places such as free-curved surfaces.

-

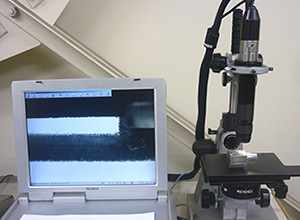

- Dimension control

- Our measuring microscopes, three-dimensional measuring machines and other measuring instruments assure accurate dimensions. A report of measured values would be provided upon request.

-

- Digitizing

- Upon request, we would obtain digital data of mold parts and final products with no blueprints nor model data, thanks to high-precision optical 3D scanners and contact-type 3D measuring machines as well as reverse engineering software.

* If our investigation reveals any suspicious/illegal requests, we must decline such digitization.

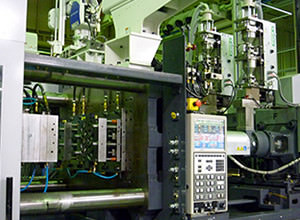

Resin injection process

Resin injection process

We determine resin injection conditions based on the product data we examined when the mold was created. As a result, the high precision injected product is possible.

-

- Prototype of injected parts

- Trial injected products would be manufactured at a low cost with short lead-time by using our prototype injection molds. As the strength of these prototype molds is similar to that of molds for mass production, they can be used to manufacture complicated shapes to a comparable quality and dimensional precision as is expected from mass production molds.

-

- Small-batch production

- Along the path from concept development, prototype production to mass production, we offer on-demand small-batch manufacturing. This would allow an early detection of possible problems on final product and make in the end the product-launch secure as expected.

Research & Development

Research & Development

We cooperate with industrial design companies and resin injection manufactures to meet your needs.

-

- Industrial design

- We offer from product's concept planning to styling design through our close relationships with design companies. Our aim is to make your design possible to produce, by considering the cost and the productivity.

-

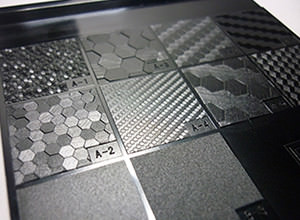

- Development of texture/surface finish

- Surface texture that decorates injected parts not only provide visual beauty and the sense of touch, but also improve the functionality of the products, such as scratch resistance or anti-fouling. According to the needs for the products, we develop and offer various kinds of textured surface finish by lazer ablation or STL milling.

-

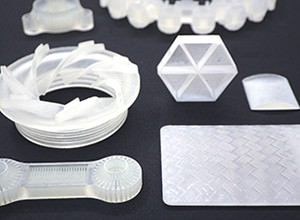

- 3D Printing

- We propose the production of prototypes and mock-ups, to verify product-design and functionality, by making samples with up to 16μm pitch on a translucent acrylic resin for checking tactile impressions prior to producing actual decorative molds. Highly detailed 3D printed example enables micro and fine decoration product with low cost and short lead-time.

-

- Optimization for mass productivity

- We bring advice, based on preliminary analysis by CAE and our many years of experience, about optimal gate positioning, about the fluidity of a specified resin in the mold, appropriate runner lengths or the possibility of weld lines, etc.

Our performance

| Decorative molds |

Products with pseudo stiches and surface texturing etc. |

| High precision injection molds for high melting thermoplastics |

PPS plugs, polishless molds etc. |

| Molds for high precision resin injection |

Oil control valves etc. |